All You Would Want To Know About Spiral Wound Gaskets

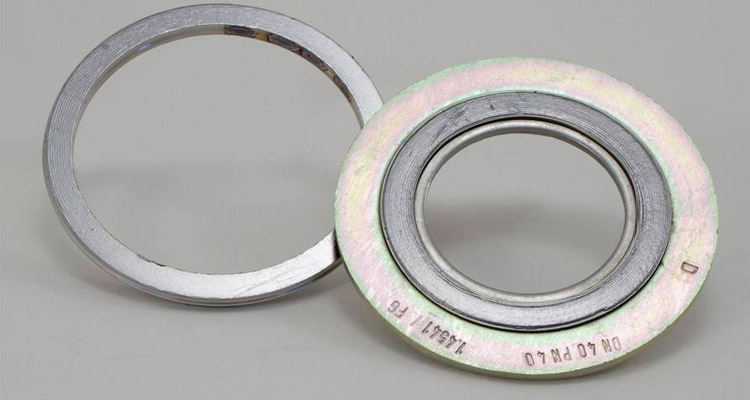

Spiral wound gaskets are semi-metallic gaskets that comprise of a mix of metallic and filler materials. These gaskets have a metal wound outwards in a circular spiral, with the filler material wound similarly, but starting from the opposite side, thus resulting in alternating layers of metal and filler material. The metal used in these gaskets is usually carbon rich or stainless steel, and the filler material generally used is flexible graphite. The metal provides structural support to the equipment, while the filler acts as a sealing element. These semi-metallic gaskets allow lower clamping forces than solid gaskets, and are used in a majority of applications. Even though they are a little costlier than other gaskets, people prefer these semi-metallic gaskets over the others. Trim Engineering Services is one of the most reliable spiral wound gasket manufacturers in India, whose products are ideal for applications that require gaskets with highest quality flexibility so that they can be effectively used in conditions with fluctuating temperatures and pressures.

How are spiral wound gaskets manufactured?

As mentioned above, spiral wound gaskets are made by winding alternating strips of metal and filler material over an inner ring made of special steel. Although the basic materials are carbon rich, stainless steel, and flexible graphite; these materials can be changed depending upon various factors. The main factors that help in deciding upon the materials to be used include chemical compatibility, fluid concentration, corrosive nature, operating temperature, and material cost. Because the spiral wound gaskets depend upon the mechanical characteristics of a formed metal spiral strip, they are particularly suitable for low or fluctuating bolt loads. However, you must keep in mind that the spiral must not be over compressed, if you require effective and long-lasting operation. The completed gasket with alternating spirals of metal and filler material is fitted into a steel ring of specified thickness. When the gasket is fitted into a flange and bolt load is applied, the outer steel ring governs the flange closure. To further enhance the gasket’s pressure rating, a steel ring can be added to the inside that also protects the windings from contamination or any similar damage.

Where are spiral wound gaskets used?

The spiral wound gaskets or semi-metallic gaskets are designed for the widest range of operating conditions of temperature and pressure. They are used in raised face flanges, male and female flanges, and tongue and groove flanges. They are also reliably used in high-temperature and high-pressure applications.

The spiral wound gaskets manufactured by Trim Engineering Services are made up of stainless steel 304, 316, or 321. The general filler materials used are graphite or asbestos. The outer ring of such gaskets is made up usually of carbon steel. The most highly recommended spiral wound gasket is the one with flange face finish of 63-250 AARH. So, for the best-in-class semi-metallic gaskets, you can get in touch with Trim Engineering Services, one of the leading and respected spiral wound gasket manufacturers in India. Other than these semi-metallic gaskets, you can also purchase from a range of metallic and non-metallic gaskets too.