How To Load Bobbins Into Machines?

There are various kinds of machines – home sewing machines, commercial machines, industrial machines, embroidery machines, and many others. And, all of these machines require different kinds of bobbins. Certain machines can sew faster and through thicker weights of fabric better than home sewing machines. The configuration of industrial and commercial sewing machines differs from that of home sewing machines. This is why the process of loading bobbins into these machines is also different.

Loading bobbins into industrial sewing machines

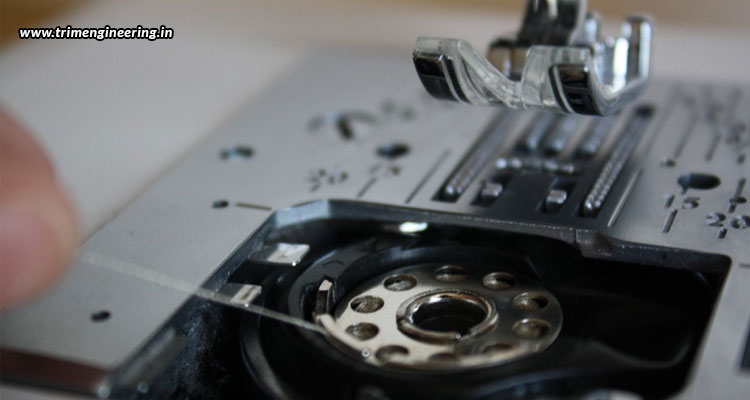

- Most industrial sewing machines are built into sewing tables or sewing desks so that an even flat sewing surface is provided. This is why industrial sewing machines have front-loading bobbins, which are located under the sewing table facing the front of the machine. Here is the process used to load bobbins into an industrial sewing machine.

- First and foremost, you need to pick up the metal bobbin, and create a one inch long thread extension. Then, you need to place the metal bobbin in the bobbin case, while making sure that the thread extension hangs free outside of the case. You can get the best kinds of metal bobbins for your machine from Trim Engineering Services, the leading metal bobbin manufacturers in India. Here, you can also get various other kinds of bobbins like wooden, aluminum, plastic, and many others.

- The next step involves pulling the thread extension, while paying attention to the direction that the bobbin is turning. If the bobbin turns clockwise, you can ensure that the case is inserted correctly. Conversely, if the bobbin turns anti-clockwise, it proves that the bobbin inserted is wrong. So, you need to remove the bobbin, flip it, and then insert it back into the bobbin case.

- Next, hold the bobbin case with the tension spring, which is a piece of metal with a hook at the end that is bolted to the case, facing upward. Then, you need to take the thread extension, and slide it through the slotted notch, under the tension spring, pulling down through the thread guide, which is the hooked end of the tension spring.

- Lastly, while holding the bobbin case in one hand, you need to lift the latch on the front of the bobbin case with the other hand, hold it, and insert the bobbin case into the rotary hook – the area that holds the bobbin in place.

Loading bobbins into home sewing machines

Today, home sewing machines have been transformed from the traditional manual ones to the more contemporary automatic ones. Here is how you can load the bobbin into such home sewing machines.

- First, you need to raise the needle to the highest position by rotating the hand wheel towards you. Then, remove the bobbin cover plate by pushing the release button to the right. This will have the bobbin cover pop up sufficiently to allow removal of the cover.

- Next, you can insert the bobbin, making sure that the bobbin rotates anticlockwise when you pull the thread (just opposite of that in the case of industrial sewing machines).

- Now, you need to pull the thread through the slot, and then to the left. With a finger held gently on the top of the bobbin, you need to pull the thread until it stops in the slot. Then, you must pull about 6 inches of thread and lead it towards the back of the machine under the pressure foot. This will assure that the bobbin thread does not slip out of position.

- Finally, replace the bobbin cover plate into the needle plate, and there, your machine is ready to sew!