Various Kinds Of Gaskets Available

The industrial sector is all modernized with the latest technologies, superior methodologies, and other commercial revolutions to provide a brand new venture to today’s generation. And, with the usage of so many chemicals, solvents, and other liquids and gases, there is a wide demand of gaskets in the manufacturing industry like spiral wound gaskets,

Leakage from the flange joint can be dangerous, especially if the leakage is of harmful gas, chemical, or any other such element. And, no manufacturing plant will want leakage of toxic or hazardous material that can harm the operators and environment. Gaskets are sealing materials placed between connecting flanges to create a static seal that helps in maintaining leakage-proof sealing in all kinds of operating conditions. Whatever type the gasket may be, the primary function of each gasket is to seal the irregularities of each face of the flange, so that there will be no leakage of the fluid from the flange joint.

Parameters that decide upon the usage of gaskets

Temperature – The material of the gasket must be able to withstand the temperature range of fluid/gas it is required to handle.

Pressure – The material of the gasket must be able to withstand the pressure range of the fluid/gas it is required to handle.

Type of liquid material – The material of the gasket must be capable of dealing with the fluid or gas involved; or the different types of fluids that it has to handle, if there are more than one fluid type involved.

Corrosion – The material of the gasket should not corrode when it comes in contact with the fluid/gas it handles.

Sturdiness – The gasket must be capable of withstanding all kinds of abrasion, vibration, and other movement caused when the machinery is in operation, or when there is any change in temperature or pressure.

Different types of gaskets

Various kinds of gaskets are used in different applications. They can be classified in many different ways; for example, by material, by function, or by application. Gaskets inherit the properties of the materials from which they are manufactured. The most common types of gaskets are –

- Rubber gaskets – Various kinds of elastomers like natural rubber, nitrile, neoprene, and EPDM can be used to build these rubber or soft material gaskets. These gaskets are used in a wide range of applications like pipe gaskets, manways, and heat exchangers.

- Cork gaskets – These gaskets are made from cork combined with elastomers bindings, to give high flexibility and compression. These gaskets are widely used in applications involving oil, fuel, and solvents.

- Non-Asbestos Gaskets – These gaskets are manufactured from compressed fiber with elastomer bindings. They are used in applications that involve acid, oil, steam, and water.

Gaskets are also generally classified into three basic groups – metallic, non-metallic, and semi-metallic gaskets.

- Metallic gaskets – These gaskets are made from soft iron, low carbon steel, and stainless steel. They are used in high-pressure class flanges, and can be used for high temperature applications. High tension bolting is required in the case of metallic gaskets. They are very robust and quite expensive.

- Non-metallic gaskets – These gaskets are made from rubber, graphite, Teflon, PTFE, and compressed non-asbestos fiber. They can easily compress with low tension bolting, and are thus used with low-pressure class flanges. These are the least expensive gaskets and are easily available.

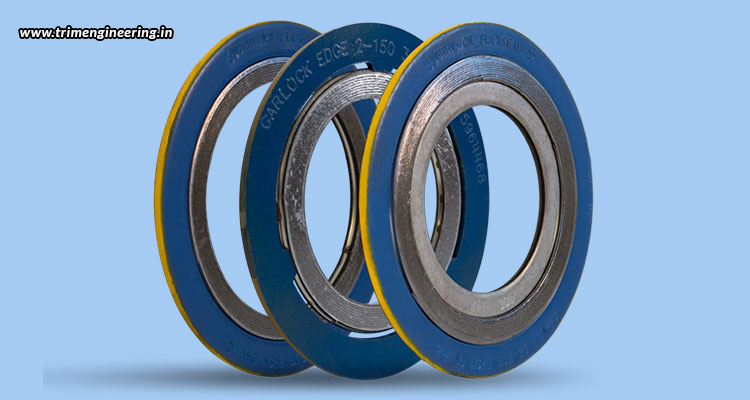

- Semi-metallic gaskets – As the name suggests, these gaskets are a combination of metal and non-metallic material. The combination depends upon the requirement of the application. The various types of semi-metallic gaskets are spiral wound, metal jacketed, and Kamprofile gaskets. They are used in a wide range of temperature and pressure applications. Trim Engineering Services is one of the finest spiral wound gaskets manufacturers in India where you can get the best products to suit your application.