Spiral Wound Or Sheet Gaskets – Which Are Better For Gearboxes?

When you plan to use a gearbox, you must understand that gaskets play a very important role in its construction. Gaskets are thin rings that sit between two surfaces playing as mechanical seals. Other than sealing, they serve various purposes of padding, minimization of vibration, leakage prevention, and protection against environmental contaminants. There are two main types of gaskets used in gearboxes, namely sheet gaskets and spiral wound gaskets. Let us take a look at both these types of gaskets, and understand their differences, functionalities, and pros and cons; so that you can make an informed decision of which one you would prefer for your gearboxes.

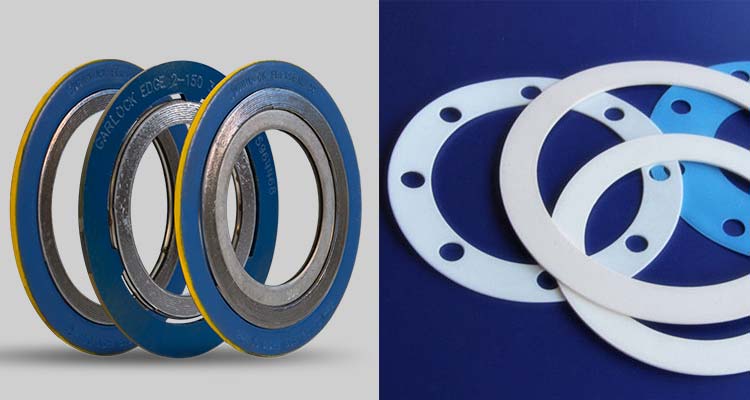

Spiral wound gaskets

Spiral wound gaskets are those that are constructed by winding a metal and filler material together in such a way that the final gasket has alternating layers of metal and filler material. The metal used in most gaskets is often stainless steel, and the filler material is generally graphite. Different manufacturers use different materials to construct their gaskets. Trim Engineering Services, one of the most respected spiral wound gasket manufacturers in India, commonly uses materials like stainless steel 304, stainless steel 316, stainless steel 321, and carbon steel metals for their gaskets, with the filler material being graphite or asbestos. However, in any case and any material used, the metal provides structural strength, while the filler acts as a seal. Spiral wound gaskets are available in various shapes like round, oval, rectangular, diamond, and pear.

Spiral wound gaskets are highly reliable in almost every kind of work environment due to spring-like padding they provide. They can work efficiently even in hot, high-pressure, and corrosive situations because their unique construction enables them to withstand changes in temperature and pressure. Because of such reliability and the strength that they come with, spiral wound gaskets can prevent gear failure and the repairing/replacement costs that come with them. Also, such gaskets require lesser clamping forces than other types of gaskets.

Sheet gaskets

A material of sheet that has the gasket shape punched out of it is a sheet gasket. Sheet gaskets are made of materials like asbestos, graphite, mineral, carbon, nitrile or synthetic rubber. No matter which substance is used, but the materials used in such gaskets are always flexible and have good recovery properties that prevent breakage during installation. Based on the type of material used, sheet gaskets can fulfill various chemical requirements associated with acids, steam, corrosive chemicals, and caustics. These gaskets are relatively very cheap and fast as compared to spiral wound gaskets, but are also crude. The two biggest advantages of sheet gaskets are that they fulfill chemical operation requirements, and are available at a very affordable price. Although sheet gaskets may look like nothing more than a flat disc with the center punched out, but they play a very crucial role in the industrial world.

So, for providing cushioning between different parts of your gearbox, you must choose an appropriate gasket to enable mechanical operations. Make your decision and approach Trim Engineering Services, one of the best sheet and spiral wound gasket manufacturers in India to provide you with the best-in-class gaskets for all your applications.