Are You Planning For A Custom-Made Gasket?

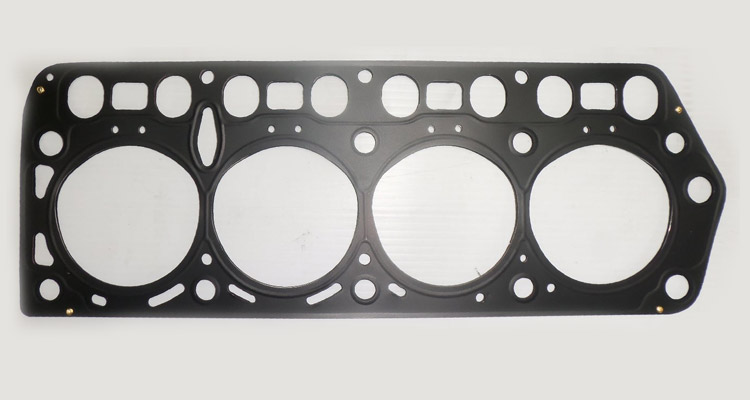

Today, customization has taken the world by storm. Whatever it may be – apparels, smartphones, cars, bikes, and more – almost anything can be customized today. Another small but considerable entity that can be customized is a gasket. Yes! The tiny element that is fit into a machine to stop leaks from or into the joined objects, when under compression, can also be customized. Now, you may ask why someone would even think about customizing the gaskets that they want to use. Well, there are a lot many reasons. Listed below are the different benefits one can have if they use customized gaskets.

Benefits of using customized gaskets

Custom gaskets can give your equipment the built-in protection that they require. If you are a manufacturer of any equipment that requires gaskets for the production line, customized gaskets are the best option as they can be built to the exact specifications needed for the application and environment too. No matter how well readily available gaskets may be, custom gaskets are a better option as compared to pre-made production-line gaskets, in any case. If you want a seal that can operate and perform well under high stress and compression that your application will be experiencing, you must use a gasket that is designed to the exact specifications. Pre-made production-line gaskets may or may not hold up the test of time, pressure, and usage that purchasers of finished products demand, but custom-made gaskets surely will! Custom-made gaskets are made to match the exact needs of the product or system for which they are designed. You can get in touch with custom spiral wound gasket manufacturers in India like Trim Engineering Services, who can understand the exact needs of your application and products, and build a gasket that is best-suited for the same.

Materials to be used in customized gaskets

The entire credit goes to today’s advanced technologies that custom gaskets can be offered in a variety of materials, and can be manufactured in massive quantities, that too to meet your exact specifications. Material selection for customized gaskets is a very important aspect. You need to choose the material that can withstand any condition – from freezing temperatures to extreme heat, to high pressure – especially the environmental conditions that your applications will have them to encounter. From a range of materials like rubber, ceramic fibers, polypropylene, styrene, PTFE, and many others, make sure you choose the most suitable and reliable one. Here again, experienced spiral wound gasket manufacturers in India can help.

Another concern that may be disturbing you is that customized gaskets are very expensive. Obviously, anything customized is a little more costly when compared to readily available products, but customized gaskets can prove to be a low-cost solution for all your production needs in the long run. When gaskets are specifically designed for the level of compression to meet your exact specifications in the material of your choice, you can be sure that they will perform well and for longer, meaning saving you repairs and replacements for a considerable amount of time. So, if you are already planning for custom-made gaskets, go ahead because it is the right choice. And, if you aren’t, then make sure you do!