Importance Of Spiral Wound Gaskets In Power Generation Industries

Today’s industrial and commercial landscape is very challenging, and we all know and agree to that. And, within this challenging landscape, every industry has their own varied number of options to provide to clients. Same goes for the power industry that has multiple options like natural gas, coal, fossil fuels, and other natural methods through which energy can be produced. Apart from these natural elements, there are other renewable methods like wind, solar energy, hydroelectricity, and biomass that help in producing energy in a variety of different ways. Now, with all these applications, come extreme temperatures and conditions, which can only be survived through with the help of durable and reliable spiral wound gaskets and sealing solutions.

Power plants require huge number of resources and large spaces of land to convert electric power on a massive scale. Electric power generation requires a multitude of power sources like coal-fired, gas-fired, oil-fired, hydro-electric, and nuclear. Regardless of the source of power, the power generation industry has high demand of flexible materials to address all kinds of thermal and electrical insulation, gasketing, and taping requirements for both turbines and generators. Therefore, the gaskets that are to be used throughout these plants must be designed in a manner that they are able to handle a wide range of operating conditions, temperatures, and pressures, in order to evenly distribute power across long distances. There are many spiral wound gasket manufacturers in India who are trying to fulfill these requirements. But, one name that you can rely upon to get your hands on the best kind of first class spiral wound gaskets is Trim Engineering Services, who is constantly working towards optimal efficiency and innovation, while working upon minimizing costs.

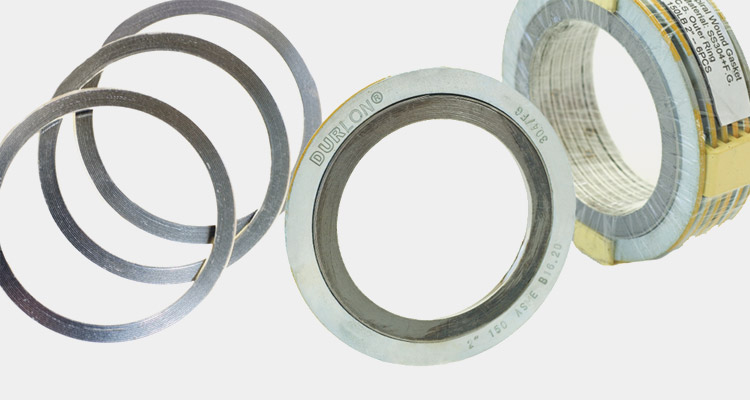

Spiral wound gaskets are built with a combination of various materials like a pre-formed metal strip that is alternated with a more compressible soft filling material, thus allowing an extremely tight and highly responsive sealing. The metal strip reacts like a spring under load pressure, which makes the seal highly flexible in every changing condition. Therefore, these spiral wound gaskets are the most versatile, ideal, and energy-saving solutions for various applications. Some of these applications include generators, cross-over pipe flanges, condenser systems, low-pressure turbines, boiler feed pumps, and lube oil systems.

At Trim Engineering Services, one of the most respectable spiral wound gasket manufacturers in India, we aim to help power generating companies to navigate through the complexities of this challenging and evolving industry in the best and easiest way possible. Our reliable gasket solutions allow such industries to easily meet the demands of their clients while gaining a competitive edge. For every requirement like natural gas, fossil fuels, turbines, generators, etc., our spiral wound gaskets are manufactured with implementation of a quality management system that complies with the ISO 9001:2008 requirements, thus ensuring continual improvement in the quality of output. Our high performance technology gaskets include a wide variety of metallic, non-metallic, and semi-metallic gaskets that you can choose from as per your requirement and demand of your application.